Mass Production on a Human Scale

Seeing the People in the Sea of People

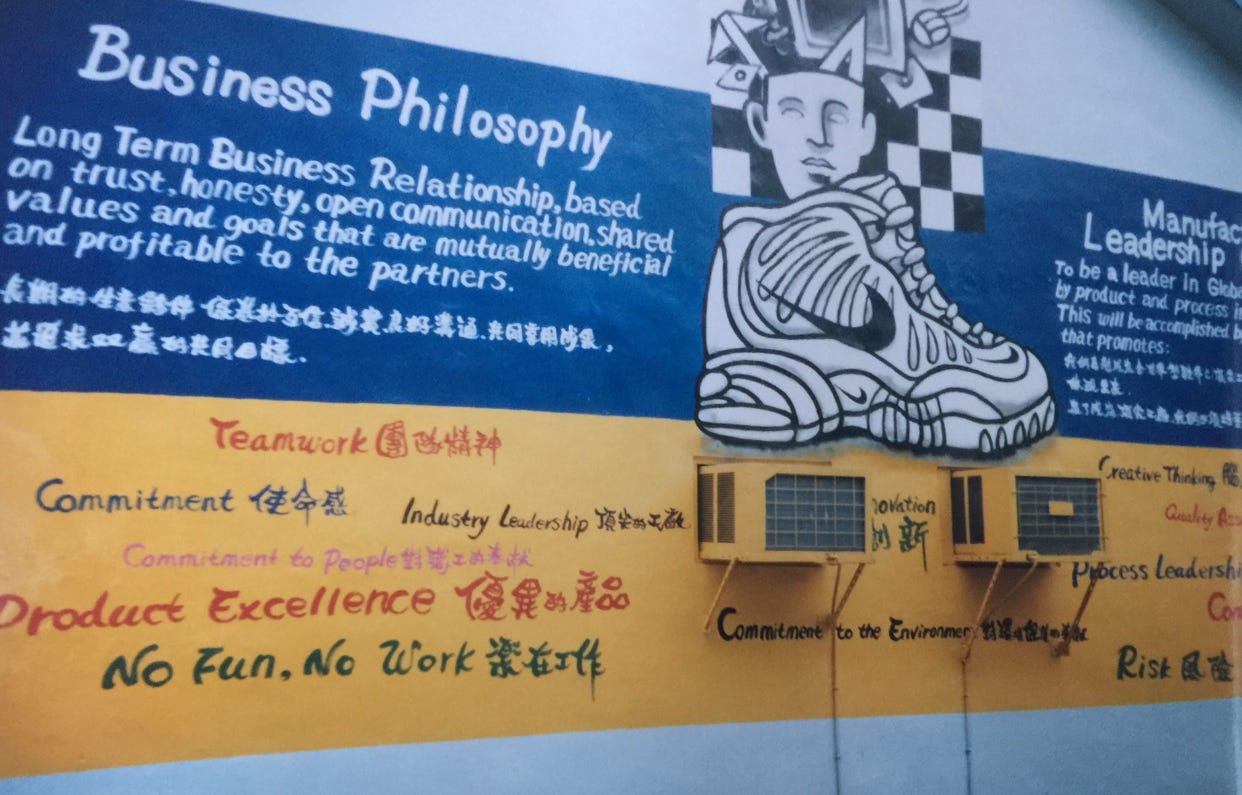

Large scale production can be daunting. On my first trip to Asia in 1997, the lead engineer in Indonesia took me to the rafters of the kids soccer shoe factory to give me a sense of what was really happening after I drew my sketch. Eddy pointed down to the 2000 people that were cutting, stitching and gluing together thousands of shoes per day. The news talked about the poor facilities and treatment, but the spectacle I witnessed from a bird’s eye was far from that brutal narrative.

The factory resembled the Ohio shops I toured in high school with uniforms intertwining between stations in a coordinated effort to turn a designer’s drawings into a customer’s footwear. The only visible differences between the Hasi Footwear Group outside of Jakarta and the Delco Moraine Plant outside of Dayton were the product, the people and the scale.

Especially the scale.

In Asia the scale is always daunting. A combination of efficiency and ego lead the companies and governments to develop oversized everything in ways that westerners find overwhelming. Americans see a loss of humanity in a visual of thousands of people. In Asia they see strength and harmony.

And with that unity comes a powerful tool that a designer must carry with responsibility. The dedication and tireless hours worked by every individual on the line was something that shouldn’t be taken for granted.

“Every time you make a change,” Eddy told me as he permanently etched that vision into my brain, “this entire team shifts their work to solve your drawing. If your drawing is poor, you slow down all of these people. Remember that.”

I did.

I often tell young designers that the most important aspect of an early design apprenticeship is having your drawings interpreted into manufacturable goods, not just 3D shapes. Everyone with a sheet of paper and a pencil can design something. The internet is overflowing with sketches of sneakers and the level of Photoshop is unbelievably intimidating. The abundance of 3D printing seduces you into believing that you know what a real shoe will look like or how it will feel.

But people don’t usually buy sketches.

The art of transforming a drawing into a three dimensional object is the first step in the process. The rise of 3D printing was supposed to skip all of these steps.

One day they will.

Until that day arrives it’s unbelievably important to know that the material edge to stitching allowance is different from distance between two needles in a double row stitch on an industrial sewing machine. It’s good to understand how the heel-ball offset manages foot strike management. It’s crucial to know how the vamp length and flexibility work hand-in-hand. Those details make all of the difference when you are asking thousands of people to execute your ideas at high speeds at high levels.

That knowledge was more than a little intimidating in my first few years of being a designer. I would often sacrifice my concepts in order to make the engineering and production execution easier. I would take the safe route and the product sometimes suffered. While we’d sell a million units on time with great margins, the product was forgettable and destined for the landfill.

I had to learn to challenge the factory — and myself — to preserve whatever magic that might lie in a sketch. That’s the real trick. Building an incredible sample is common when you want to be daring. Small fashion companies can crank out 500 pairs of provocative product at $1500 per pair on a seasonal basis. And 5 million pairs of been-there-done-that is simply an exercise in accounting and engineering.

The sweet spot is producing that improbable concept so people cherish them at the point of purchase and keep them beyond their usefulness because the mass produced piece of art you created is too compelling to simply throw away. You don’t find Foamposites or Timberlands in the trash. You just don’t.

The sweat and arguments and long nights that lead to those items of desire get resolved at the development level — the intimate side of the factory. A team of 5–100 product managers and engineers will help you resolve your design into something that is ready for manufacturing. Depending on the country and factory, the language barriers compete with the laws of thermodynamics and the properties of rubber and leather conflict with the margin requirements for profitability. Something may look great in a sample but will suffer painfully in production. A great development center will know the difference.

The teams of marketing and sales that don’t care what happens under the hood want to see the magic in the boxes that they open in their air conditioned showrooms back in Oregon or LA or Boston or NYC. They don’t get to stand in the mold shops of Vietnam in August to argue over 3.0 millimeters of steel.

Their loss.

At some point I came to grips with my fear of upsetting the thousands of people putting their hands toward my sketch. My first hurdle was the concept of these workers being people. While I never witnessed any mistreatment of factory workers or management, it was difficult to shake the vibe that these people of color were being treated as lesser because of where they were born. It took several trips before I learned enough about Taiwan and China and Indonesia and Vietnam and Korea to have an appreciation for how each country and culture handled business, treated it’s people and worked with outsiders.

Most of the expats I came in contact with were phenomenal in their appreciation of the culture that they found themselves embedded in. Their connection with the communities, their staff and their work helped me to connect in real ways with everyone committed to doing their job. Some of the developers married locally. Some engineers even adopted children within the country. Their appreciation for the people wanting to earn a living in a safe environment was pure.

It was the few expats that abused their power as a colonizer that live at the heart of my uneasiness. At home in the US or Europe this developer/engineer would be an ordinary individual, but in a land where their skin color and company support made them wealthy by default allowed them to rule with an iron fist. The expression that is casually thrown around to demonize those that exploit their workers is ‘slave labor’. For me, that was always the lens through which I watched the people I interacted with.

It took some time for me to differentiate between these two groups of expats entangled in Asian production because the signals were much deeper than the surface.

In the 80’s and 90’s it was commonplace for ‘American’ names to be given to English speaking Asians as a way for them to find work in a growing global business environment. “Please call me Jane,” was a typical introduction.

I hated this.

But they were so proud of their western names that when I would try to learn their real names they wanted no part of it. The assimilation that I had trouble with was a badge of honor that they had earned. At the time it was their mark of achievement. And each country was different. In Korea you learned initials because they were ‘easier’ than names. And each community evolves at it’s own speed. I hear more Chinese names in China today. Each generation has designed their comfort level with how they fit into the global economy.

Back then, I was still trying to figure out what time zone I was in.

So when I discovered expats that went the extra mile to learn the language I assumed that they truly cared about the people.

Bad assumption.

While learning the language could be used as a way to connect in a positive way, it also offered the opportunity to demean and disrespect people in the language they thought might offer them protection. I watched individuals that held zero power on US soil bark orders in their new language.

So it took some time to determine which people were simply trying to be compassionate leaders and which people were enjoying their power a bit too much.

Eventually I learned enough about the cultures and the characters involved to then focus on the job at hand. And that’s when I learned to fully appreciate the factory as a whole. I knew when to push and pull on a level that was respectful, so I was ready to chase the magic from the sketch.

The time it took for me to develop that sense of ease slowed my skill development but once I learned to communicate on a level that was comfortable for me, my work improved in leaps and bounds. My technical packages became much more refined and my revisions resolved issues quicker. On the other side of the water I learned that they appreciated my approach and were happy to support me, even if my requests were demanding.

I would learn from other designers of color that this slower development and subsequent rise of acceptance was common. When you can identify with a workforce in a way that shares their understanding of assimilation within Western culture, you treat them like human beings in a broader consideration. For example, people who have worked in a restaurant treat people who work in a restaurant with a deeper appreciation for what they do. They are more respectful of their time and energy. But they also know when the service is terrible.

When you can relate to a workforce in a meaningful way, they respect and support you. I am always amazed when I watch sports fan yell derogatory statements at players on courts and fields because they paid their money. They aren’t taking into account for one second that the player receiving the verbal abuse is someone’s son or daughter or father or mother. When you have a parent or a child or a friend that is an athlete, you don’t berate athletes in such a casual way. You just don’t.

Athletes can feel that connection when you treat them like people. Waitresses will give you that free dessert if you acknowledge that they are people. The factory employees will support you when they feel that respect.

That support and my evolving skills lead to better product which lead to better sales which lead to bigger orders which lead to more factory support.

That’s how the cycle works.

So instead of worrying about the cultural clumsiness that dominated most of my early visits, I found myself requesting tours of the stitching areas so I could try to impress the staff with my bad craftsmanship and technique. I never learned to stitch or speak the languages, but I knew that a face that smiled in their work areas would help them understand that I was a person who understood that they were people too.

Now, I was having fun.

The two hour factory dinners and the bad karaoke and the drinking in any form were never my thing. The 16 hour flights and 90 minute van rides are still a chore.

But when you walk into a room to see the engineering blueprints, wooden models and stitched uppers on a table flanked by the people ready to turn your scribbles into something real, you become a kid in a candy shop. The rubber book with 400 textures and countless material books you have to sort through are better when you are around the corner from the humming sewing machines. The two day challenge of seamlessly merging the TPU sidewall with rubber outsole because it will be the only thing you think of when people are buying them like candy three years from now.

The heat tunnel. The laser machine. The cutting dies. The sample material hallways. The Coca-Cola products reserved for good company. The WeChat Family photos. The sighs of frustration when you ask for better execution. The smiles of pride when you write confirmed.

My roadblocks with factories were never about the work. I love making things. My hurdles dealt with what is casually referred to as colonization, assimilation and exploitation on soil that was foreign but with visuals that were all too familiar.

I recently visited a factory group that I had not seen in 15 years. I recognized a familiar face that easily stood out. Kite stands 6’4” in Taiwan, so he’s difficult to miss. Before I can ask him if he remembers me, Kite announces my full name and the projects we worked on that I’d long forgotten.

As I tour a production facility 90 minutes outside of Zhengzhou I learn about the migration of facilities within China. The workers that filled factories in major cities like Guangzhou had become too expensive to hire. Their home cities were blossoming with the money they’d brought back over the last 15 years. Moving to the big city for a good job in the factory was no longer necessary.

So the factories have adapted to this lack of migration by moving production facilities closer to where those workers lived.

But the internet caused a new disruption.

Young people found ways to make money on the internet — writing mobile apps and selling rare sneakers — so the job at the factory became less interesting. Their replacement has been mothers looking to provide additional income. So factories have provided schools for their children and programs to help them develop their management skills because future leaders always came from the factory floor.

Large factories that work with multinational brands have no choice but to run a socio- and environmentally ethical company. The government and their customers demand high standards, so these better factories are far from worrisome. It would be bad business to run a sweatshop these days. Of course, there are rule breakers that knockoff brands and treat works poorly. But the quality of their business operations matches the quality of their production, which is far from acceptable for most global consumers.

The equipment needed to develop, test and manufacture at this scale is daunting. Specialized knitting machines from Japan and precision testing devices from Taiwan are expensive to own and operate. The thousands of people that keep these big engines moving can look intimidating. But an understanding of the job at hand and the culture of the country, helps with perspective.

Over the next couple of years I’m working with factory partners in Asia to develop product creation facilities in the U.S. They understand the opportunity that local production offers consumers and workers. We want to make those skills global. But it started for me 20 years ago in Taiwan and Indonesia.

Today I can relate to countries, cultures and people without sacrificing style, performance and quality. I can be understanding without losing the magic inherent in a napkin sketch.

Yet, the real trick is doing this while avoiding beef stomach, second-hand smoke and Moutai.

Good things.